-

- ыэь ыАъГЕь ь ьЕъГ эьЇь ььЌыЅМ ььАэъИА ьэД ы Иы ЅэЉыыЄ.

- Polyurethane Resin

- Goods View

- DHP-1000 Soft Foam Type DHP-3000 Flexible Foam Type DHP-4000 Semi-Rigid Type DHP-2000 Rigid Foam Type Ultra Con High Strength Type Ultra Pack High Flexible Type

-

Polyurethane Resin

Ultra Pack High Flexible Type

- Price

- inquiry

- Feature & Purpose

- Dual Component High Flexible Polyurethane Resin

- attached file

- attached file2

ULTRA PACK is self-reacting type Hydrophobic Type 2 Component Polyurethane Resin which is invented by using polyether polyol. It is applied to waterstop leakage section of place where vibration occurs and it is high elasticity reinforcement urethane that reinforces dry crack caused by defect of concrete structure and buildings. Foam rate that reacts with water is minimized. This is restrained non-discharge & low-discharge waterstop material that hardened foam is harder than normal polyurethane foam and also density is high. Therefore, it does not have defects caused by deformation and it waterstop effects last semi-permanently. It provides strong physical strength after hardened. Furthermore, low viscosity and strong penetration ability through the aged weaken part brings excellent adhesive power to provide waterstop ability and reinforcement result. It is high elastic polyurethane reinforcement material. Hardened composition has high elastic property therefore it cannot be fractured by compression test.

Hardened composition has high elastic property therefore it cannot be fractured by compression test. Since it is self-reactive type 2 component type polyurethane resin, it has strong adhesive strength and high elasticity on both wet and dry cracks. Also it will provide reinforcement result.

Since it is self-reactive type 2 component type polyurethane resin, it has strong adhesive strength and high elasticity on both wet and dry cracks. Also it will provide reinforcement result. Low viscosity will allow to penetrate into minute leakage spot and provides excellent waterstop effect and also very easy to inject.

Low viscosity will allow to penetrate into minute leakage spot and provides excellent waterstop effect and also very easy to inject. When main component and hardening component is mixed you have enough working time (about 60~100min), therefore you can inject it by using 1 component type pump. And you can control the hardening time freely by adding catalyst.

When main component and hardening component is mixed you have enough working time (about 60~100min), therefore you can inject it by using 1 component type pump. And you can control the hardening time freely by adding catalyst. Waterstops and reinforces joint leaking section of tunnel and box structure

Waterstops and reinforces joint leaking section of tunnel and box structure Waterstops and reinforces crack leakage section of structure that accompanies movementNormally it can be used to waterstop all types of concrete structures and buildings when there is a leak. Especially it can reinforce and waterstops cracks and joint section of concrete constructions. It can be applied on following places

Waterstops and reinforces crack leakage section of structure that accompanies movementNormally it can be used to waterstop all types of concrete structures and buildings when there is a leak. Especially it can reinforce and waterstops cracks and joint section of concrete constructions. It can be applied on following places

Waterstops for leaking section of basement parking lot and underground concrete structure.

Waterstops for leaking section of basement parking lot and underground concrete structure. Waterstops for leakage of concrete joint section.

Waterstops for leakage of concrete joint section. Waterstops for leakage section where humidity and dryness is mixed up together.

Waterstops for leakage section where humidity and dryness is mixed up together.Ultra Pack Dimension Details Ultra Pack Dimension Details Classification Main Component Hardening Component Remarks Exterior Appearance No Color Dark Brown Liquid - Mixing Rate 100 100 Weight Ratio Specific Gravity 1.0 ± 0.1 1.0 ± 0.1 23±0.5т Viscosity 150 ~ 200 150 ~ 250 23±0.5т Mixture Viscosity 200 ± 100 23±0.5т Working Time(Hours) 60 23±0.5т Hardening Time(Hours) 24 - Packing Unit 10kg 10kg - Ultra Pack Property Data Ultra Pack Property Data Test Category Result Value Base Value Test Method Viscosity( mPa,s ) 190 Under 300 KS F 4923 Seal Strength( N/у ) 2.5 Over 1 Seal Breaking Expansion Rate ( % ) 65 over 50 Adhesive Strength( N/у ) 3.4 over 3 Hardening Contraction Rate( % ) 1.8 Under 10 Heating Change Weight Change Rate( % ) 1.0 Under 5 (110±3т,168hr) Volume Change Rate( % ) 1.2 Under 5

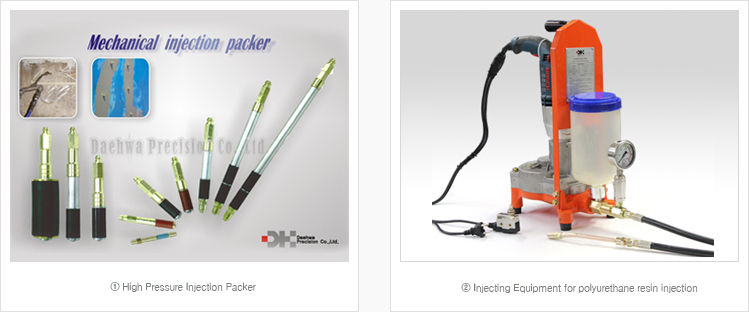

т It is specially designed to endure high pressure that is applied. Injected resin won't flow backward and this packer is also specially designed not to leak resin around stabilized and fixed packer.

тЁ This is 1 component type high-pressure injection equipment that is specially manufactured to fill on a leakage and fracture spot by using polyurethane foam and epoxy injection material. Preparation

PreparationPrepare around leaking and fracturing spot and fixate packer. Normally when injecting polyurethane foam, it is injected through packer generally. During the perforation use hammer drill and make holes with same diameter. External diameter of Drill Bit should be 10mm. Perforation angle between concrete surface and crack should keep 45 degree angle or under. If it is possible, then make position of perforation hole that contacts crack as thick as 1/2~2/3 of concrete thickness. If the concrete thickness is less than 10cm then directly perforate to fractured spot. If the thickness is 10cm~50cm, perforate in the distance of 1/5 thickness of the concrete. Conduct it around fractured spot with 20cm interval and perforate in zigzag.  Packer Installation

Packer InstallationSelect the suitable packer out of various kinds of packers that suits the most according to field circumstance. And use T-box wrench and firmly tighten up the packer to perforated hole and make sure not to bounce off by counter pressure. (It might get damaged if it is tightened too hard.)  Polyurethane Injection

Polyurethane InjectionInject Ultra Pack(High Elasticity Polyurethane) by using high-pressure injection equipment or grease gun. Maintain initial injection pressure about 40kg/cm²÷ and keep injecting until waterstop material flows out through fractured spot. Halt injecting for a few minutes when Ultra Pack(High Elasticity Polyurethane) flows out grossly between cracks during first PACKER injection, then injected foam will foam completely and it will become as seal material. For next injection operation, Ultra Pack(High Elasticity Polyurethane) will fill up the cracks well enough. After 5 minutes, start to re-inject. You can ignore the chemicals that leaks out little bit, even you can check injection status. If the crack is very big then conduct sealing before injection. т Does the water inside of the crack come out caused by Polyurethane Foam Waterstop injection! тЁ Does the injected Foam react with water and come out from the cracks after gradually foaming! тЂ Finally, does the undiluted liquid of Polyurethane Foam slides out between the cracks before it starts foaming! If it is so then the injection is properly done.  Removing Packer

Removing PackerUse vice pliers as a tool or bend off or use hammer to remove it.

If there is wet spot left then inject Polyurethane Foam again. Finishing Operation

Finishing OperationRemove Ultra Pack(High Elasticity Polyurethane) that is smeared around cracked area.

Spread with flexible sealing material (DH-CF30 Crack Cover Material)- When you treating medical fluid, make sure you wear protective helmet, goggle clothes and other protective devices.

- If the medical fluid is smeared on your skin, wash it off immediately and clean up with soapy water.

- All the hand tools and equipments that are used for this operation should be cleaned with thinner thoroughly.

- If you are working in sealed room, then make sure to conduct constraint ventilation for clean air.

- If the medical fluid is smeared on your skin and causes skin trouble, then you should go see specialist for prescription.

- If the temperature is below 5т, then you must artificially raise up the temperature of medical fluid. This way you can get proper Pot Life.

- If the atmosphere temperature is high and the area is humid, Pot Life of medical fluid quickens. On the contrary, Pot Life will slow down in low temperature area.

- Be aware of it before you conduct the operation.Recommended temperature for storage is 10~25т with no moisture. Store it in cool area. Storing period is about 6 months in sealed condition however it can be corrupted according to storing area and conditions. Preferably use it as soon as possible. This product is packed with nitrogen gas. Once seal is removed, then use it as soon as possible.

Main Contents

-

Daehwa Precision

-

Mechanical injection packer

-

concrete crack injection repair

-

concrete repair kits

-

Single component Injection Pump

-

Twin Line Injection Pump

-

Acrylic Injection Pump

-

Grouting Injection Pump

-

grouting injection

-

polyurethane injection system

-

resin injection pump

-

repair of concrete

-

epoxy injections

-

epoxy injection system

-

epoxy injection systems

-

concrete repair epoxy injection

-

Water stop grouting Method

-

Reinjector Injection Method

-

Syringe Injection Method

-

concrete repair epoxy mortar